DIY Shed Door! You know those projects you procrastinate, something that just sits around unfinished for years? Until finally, you just can’t take it anymore and the time arrives for getting ‘er done? Yep, that’s this project.

For four years now, the shed at the my downtown property has been wide open! And while it always bugged me, it just kept holding it’s position at the bottom of the to-do list. Until now.

When I bought the property, there was only 1 plank with hinges for a door. lol And it wasn’t high on the list of priorities but with an upcoming photo shoot of the short term rental apartment (Suite Thyme) AND with the only quiet seating area right there beside it AND with summer coming, that eye sore worked it’s way to the top of the list.

Before: just a small shed, filled with dead leaves, probably home to a few squirrels and lots of spiders. ::shudders::

An old fence gate propped up…really didn’t serve any purpose. Other than it just came with the property and found it’s way there. I don’t even know how it got there. haha!

And so…

Supplies I used for a custom 22.5 x 75 inch shed door:

- OSB cut to size.

- (5) 1×3 pine boards – I just guessed on what I’d need for all of the wood pieces and over-estimated a bit. I never mind having extra on hand.

- (3) 1×2 pine boards

- (2) 1×1 pine boards

- (1) paintable outdoor rated caulk

- (1) outdoor rated adhesive

- (2) outdoor rated primer

- outdoor rated paint

- this handle

- this hasp

- these hinges (not used, more on that later)

What I did:

After measuring the space (and believe me, nothing in this old late 1800s property is square…so frustrating), Russ cut an old piece of OSB to size for me to use as my base. OSB isn’t the best product for an outdoor project, but this is the first door I’ve ever built and this was the best and easiest way for me personally to test my design skills. Fingers crossed that with it being the inside of the door/in the shed and that it’s good and sealed, that it works just fine longer term.

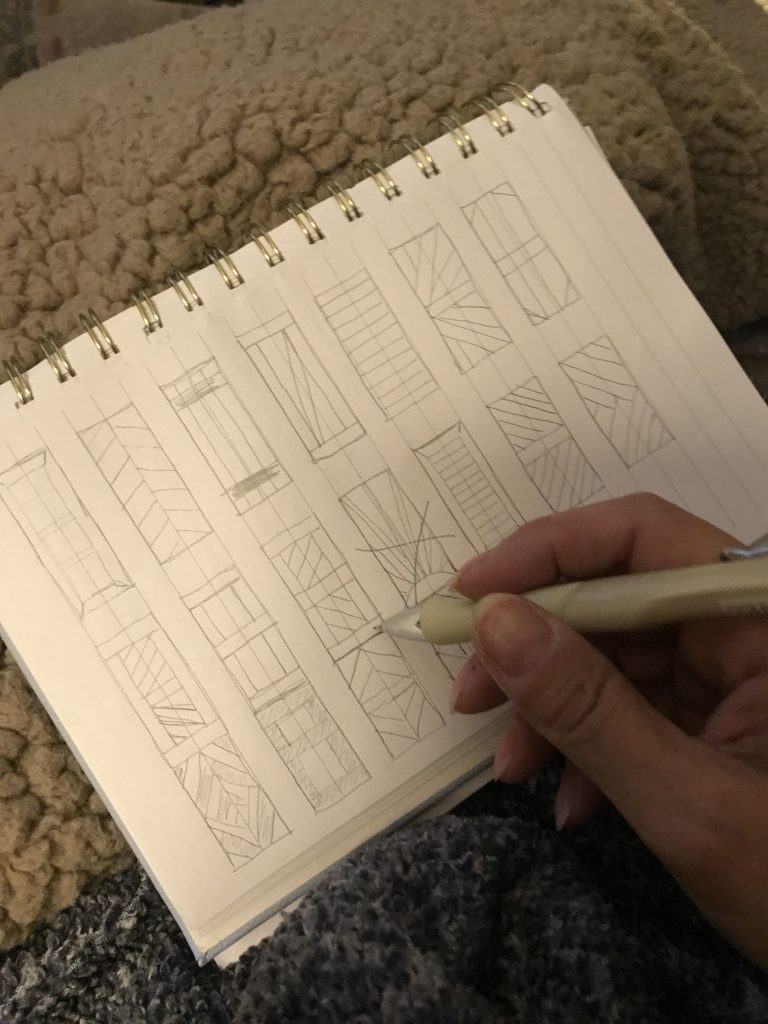

I then set about sketching up some inspiration, nothing to scale but I wanted to get an idea of what I was going for. Something with a little more detail and style than the standard barn style shed door.

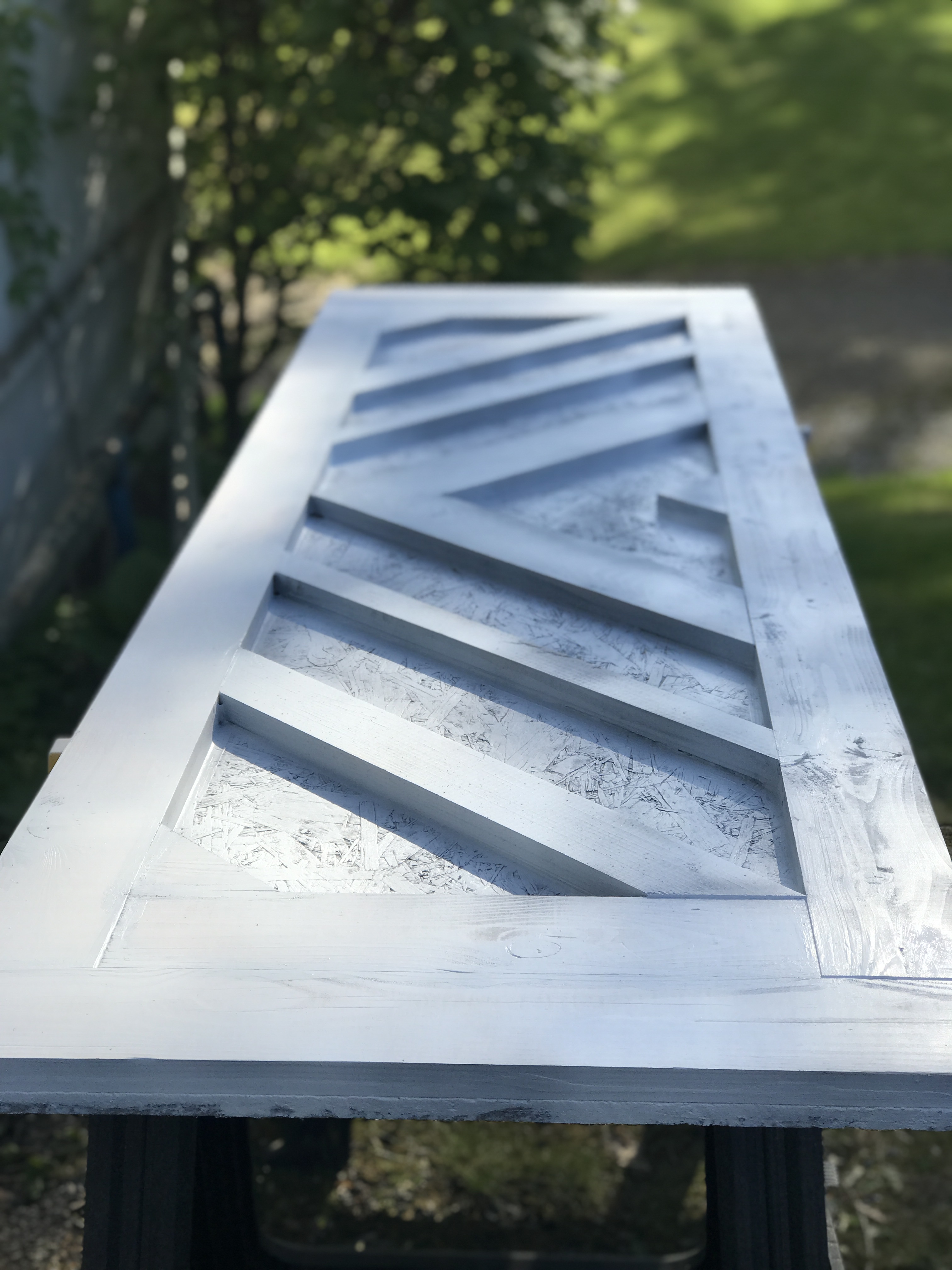

Then I set the OSB on saw horses and created a frame on the face of it with 1x3s.

I messed around with the pieces a few times before I decided on a pattern.

Utilizing a mix of mitered 1x3s, 1x2s and 1x1s, I settled on a chevron design. I enjoyed this part, like putting together a puzzle.

After cutting each piece, I adhered them to the OSB base with adhesive and clamped the edges and weighted the pieces where the clamps couldn’t reach. I did notice what putting them together with adhesive is different than just laying them out and re-cut 2 mitered pieces for a better fit during this process.

Once dry, I caulked all of the joints and cracks.

Then applied a coat of primer. I used a spray primer but next time, I’d go with (and recommend) applying with a brush and roller.

All sides got two coats of paint.

And … tada!

Time to hang. The sizing was pretty much spot on but we did have to make a few adjustments and the new hinges gave us such a hard time that after about an hour, we decided to utilize the old original hinges which took about 10 minutes! Live and learn. lol

Now there’s no longer a gaping hole! Guests enjoying the outdoor seating probably won’t think much of it but I do think they’ll notice. And I’m happy to have a place for outdoor yard tools, pots and salt for winter.

from Home Improvements Articles and News https://diyshowoff.com/2021/11/01/diy-shed-door/

![Validate my RSS feed [Valid RSS]](valid-rss-rogers.png)